Главная

Польза системы

IDM Online is not just monitoring — it manages reliability through analytics.

Problem

Rotating equipment fails without warning

At the plant, failures do not align with the maintenance schedule. Bearing failures, coupling misalignment, and increasing vibrations all occur when maintenance isn’t planned. Unplanned downtime impacts the budget, deadlines, and customer trust.

If you can’t see inside the equipment, you can’t manage its condition.

Solution

Data-driven analytics reveal the true condition of the equipment.

IDM Online is an industrial online monitoring system developed by LLP “Promprivod” and LLP “Promanalytika.” It combines classical vibration diagnostics with generative AI trained on tens of thousands of industrial cases.

The system analyzes:

Analyzes vibration, temperature, and rotational speed in real time

Detects deviations in the operation of pumps, gearboxes, fans, and other equipment at an early stage

Provides reliable failure predictions 2–4 months before actual equipment breakdowns or malfunctions

Evaluates remaining service life and recommends actions before a critical condition occurs

Specific Benefits for Your Operations

Monitor parameters and manage equipment condition based on facts, not reactions. IDM Online shows how long a component will operate before failure and what actions to take in advance to prevent breakdowns.

01

Reduce failures without increasing maintenance costs

02

Extend the service life of bearings, couplings, and shafts

03

Switch from scheduled maintenance to condition-based maintenance

04

Receive forecasts and reports in your preferred format 24/7

How We Prevented Breakdowns and Downtime

JSC “Qarmet”

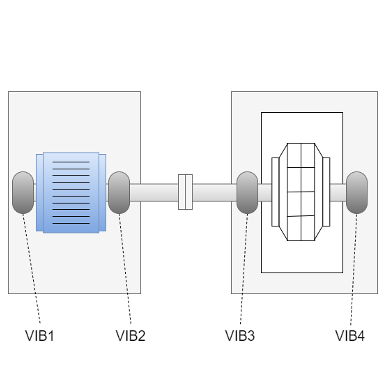

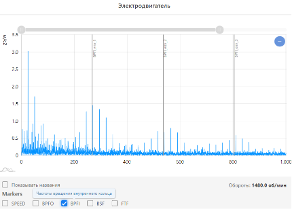

The system detected mechanical loosening of the electric drive’s bearing. After the repair work, vibration velocity levels returned to normal ranges.

LLP “KAZ Minerals”

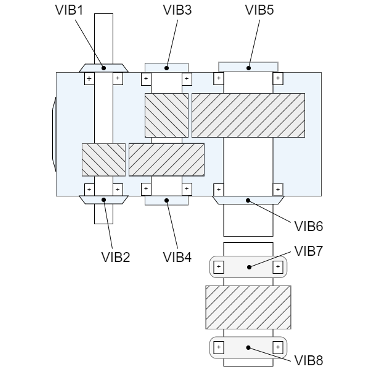

The IDM system effectively predicted defects in the 1.5 MW motor bearing, which made it possible to replace it in time.

JSC “Almalyk MMC”

Based on the information provided by the IDM-Online system, the operations team was able to quickly select the right moment and adjust the contact pattern of the ring gear.

PC “Kaztsinkmash”

The system indicated uneven radial interference and insufficient lubrication.

During the shutdown, the operations team reassembled the bearing unit and applied lubrication

Why Our System

Is Better Than Manual Monitoring

Rates for Your Business Needs

Cost of implementing the monitoring system, excluding VAT

Want more details? We’ll explain how the system works, what suits your needs, and how quickly everything can be up and running.

FAQ: Frequently Asked Questions

We’ve answered frequently asked questions to help dispel doubts, understand the technologies, and feel confident in your decision.

What if the system makes a mistake and misses a breakdown?

IDM-Online continuously monitors equipment across multiple parameters and uses AI to detect even the slightest deviations in time. In case of any ambiguous situation, the data is additionally verified by engineers, minimizing the risk of missing a breakdown.

How quickly can I implement IDM-Online at my facility?

Implementing IDM-Online takes about 12 weeks, including delivery, installation, and commissioning. After that, monitoring operates continuously.

How can I convince management that the system will pay off?

IDM-Online detects defects in advance, allowing you to extend equipment life and avoid unplanned downtime. The economic benefit is reflected in reduced repair costs and increased productivity. If you know the cost of one hour of downtime for critical equipment, we can help calculate the payback period for implementing our system.

How difficult is it to work with the system? Do I need training?

IDM-Online is designed to be user-friendly: the system automatically analyzes data and provides clear recommendations. Training takes minimal time, and the team receives ready-made reports and notifications in a convenient format.

My industry is non-standard. Will your system suit my case?

IDM-Online can be configured for specific equipment and has already been used on various types of machinery — from mills and gearboxes to pumps and fans. For non-standard industries, our team is ready to adapt the system to your needs.