What IDM-online can do?

Analyses measuring results of:

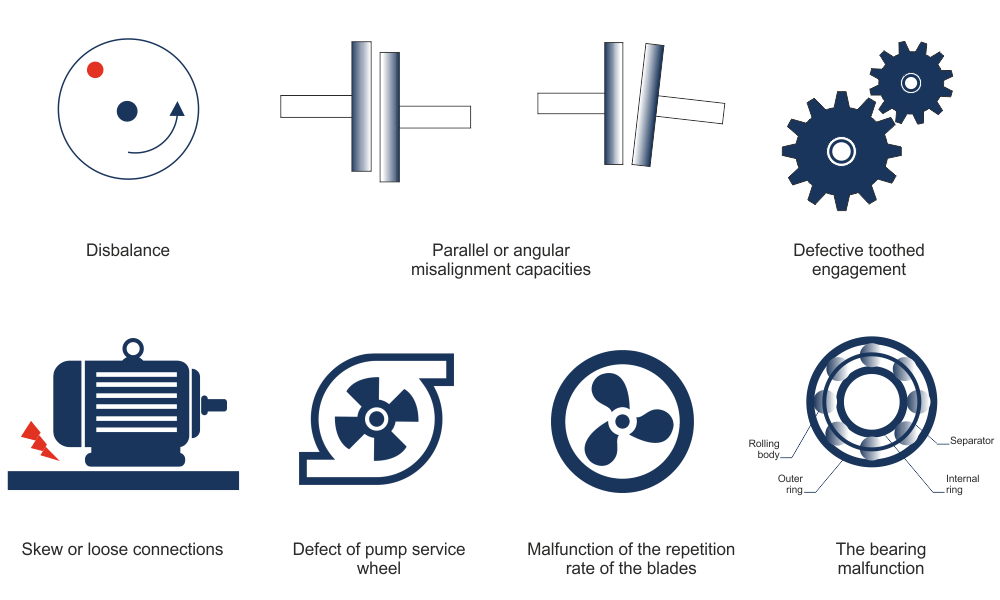

- vibration

- rotation speed

- temperature

- oil quality

Evaluates the condition of rotating equipment.

Timely maintenance work (balancing, alignment, adjustment, etc.) will help significantly extend the lifetime of the equipment.

For example, timely detected and corrected imbalance or misalignment increases average service lifetime of bearings and clutches, decreases the quantity of unplanned shutdowns.

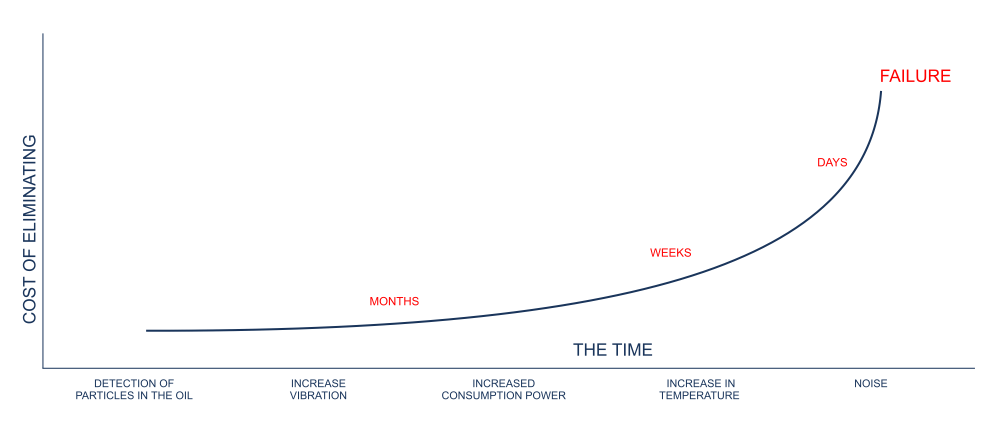

EARLY PREDICTION OF ROTARY EQUIPMENT FAILURE

The majority of defects have diagnostic features that allow to detect their origin and development. Oil and vibration-based monitoring of the condition identifies malfunctions at an early stage, well before they cause the equipment to fail.

What can be done:

-

- predict the lifetime of the equipment and perform maintenance at the time, when it’s necessary

- schedule specific works and spare parts in maintenance planning

- avoid unexpected shutdowns